Sustainability

Sustainable development

For Codelco sustainable development is a fundamental support for its current business and future development. It is embedded in the Statement of Values and the Code of Conduct and Business Ethics, to which the Company assigns the highest priority. In turn, the Sustainable Development Policy sets out Codelco’s commitment to sustainability and social responsibility, as an integral part of the business project.

At Codelco, sustainable development is based on a model which incorporated: occupational health, safety, environment, territory and community management; as well as efficient use of natural resources, and market defence and development. This approach guides social responsibility in how the Company manages its business and permits it to obtain a social licence to operate, develop new entrepreneurial activities and market its products.

This development management is implemented from the organisation’s first level and it is primarily under the Development and Sustainability Vice- Presidency, which reflects the importance and value the Company gives these issues.

The divisions have occupational health, safety and sustainability managements, in line with their specific operational responsibilities and in the top level division structure. The divisions also have policies, plans and programmes related to this subject and all have occupational health, safety and environmental certifications in conformity with ISO 14001 and OHSAS 18001.

Dow Jones Sustainability Index

In 2010 was the first time Codelco decided to be externally assessed according to the criteria applied by Dow Jones Sustainability Index, an indicator that assesses the sustainability of leading companies worldwide. The analysis of the sustainability criteria ranked Codelco ninth among 41 companies in the mining sector, which positions it in 11% among mining sector leaders.

Safety

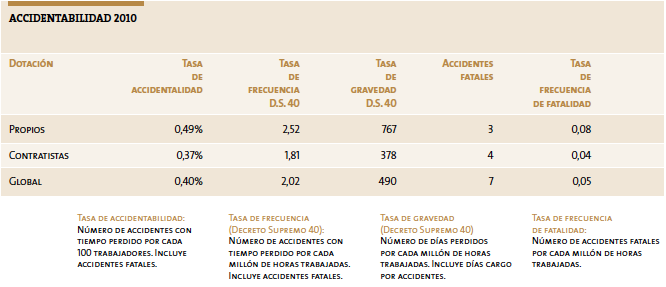

In 2010, Codelco deeply regretted the death of seven workers, three employees and four contractors. This negative situation forces the Company to deepen its efforts to eliminate high risk incidents that cause fatalities at its operations.

Nevertheless, in 2010 Codelco achieved the lowest disabling injury frequency rate in its history, with 2.04 injuries per million hours worked. This is the result of Codelco’s ongoing commitment to put into practice its first value; respect for life. The severity rate, however, was higher than in 2009, it reached 490 for both employees and contractors.

Some of the safety actions taken in 2010 were:

- Development of a corporate project to strengthen leadership and foster a safety culture targeting first-level executives and supervisors.

- Official corporate guidelines to investigate fatal, serious and high potential incidents, applied while investigating fatal incidents during the year.

- Launched verification, monitoring and analysis study of fatal incident investigation, which occurred in Codelco between January 2008 and October 2010.

- Began preparation of Rules for Life compliance standards.

- Implemented Green Card at all operations (except Ventanas).

- Implemented behavioural safety plans at all Divisions.

Occupational Health and Safety

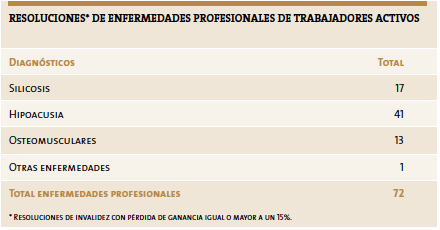

During 2010, the new resolutions on occupational illnesses affecting active workers are listed below:

Codelco continues its systematic occupational health and safety activities focused on prevention, detection and treatment of occupational illnesses that affects its own employees.

In the framework of the Global Programme for the Elimination of Silicosis from the World by 2030, Codelco held the seminar Towards Mining without Silicosis, in order to communicate the current situation of Codelco operations in terms of dust control and creation of a coordination entity to address the programme. The Company also actively participated in the technical entities created by the Ministry of Health to implement the National Plan for the Elimination of Silicosis.

In 2010, a Procedure Manual on Dust Control in Mining was prepared.

As for contractors, Codelco and administrative entities of Law 16.744 (employee mutual insurance and ISL) reached an agreement on employee preemployment and employment medical examinations and screening. This will enable mining companies to have uniform standards and it will facilitateemployee transfers, simplifying procedures, reducing costs and avoiding unnecessary medical examinations.

In industrial health, a new version of Codelco’s Risk Roadmap was launched, available on the intranet. The map identifies occupational risks in the workplace, so that employees know the health hazards to which they may be exposed and could lead to an occupational illness. This is the basis for health risk management.

Additionally, an information platform was launched with occupational health, safety, and industrial health modules for all Divisions, which will cover all the information gaps and optimise management related to medical, accident prevention and occupational illness processes, enabling synergies and traceability.

Investment in occupational health and safety

In 2010, Codelco invested US$ 145.6 million in projects to improve working conditions and habitability of different mining operations. Some of the key projects were as follows:

Codelco Norte Division

- Transfer of central chemical laboratory.

Salvador Division

- Improvement of fugitive gas emissions.

Andina Division

- Water Standardisation-Stage I.

El Teniente Division

- Infrastructure restoration and installation after February 2010 earthquake.

Ventanas Division

- Improvement of canteen safety conditions.

Â

Environmental performance

In 2010, Codelco developed plans and programmes to mitigate the environmental impact of its mining operations and processes, decide on historic socioenvironmental assets and make viable its growth projects. Key implementations were:

Â

Water Resources

Aware that water shortage is a global and local problem, Codelco reuses an average of seven times every drop of freshwater.

In 2010, a major boost was given to water resources management, which materialised at the First Corporate Water Conference. The main outcome of this conference was that Codelco’s Water Resources Master Plan was reviewed and updated and specific programme on resource instrumentation was created for all divisions.

These programmes aim to report Codelco’s freshwater extraction to authorities and other stakeholders.

Solid Waste

The Company carried out responsible industrial waste management. In December 2010 a new version of the Corporate Guidelines on Solid Industrial Waste was launched, which replaces the 2003 version.

In conformity with the advances in public policies and the development of this topic in Chile, the 2010 Guidelines provide the basis to ensure the sustainable management of solid industrial waste, minimising its generation, controlling potential impacts on the environment and looking for added value in each management stage, from origin to disposal. This is done by setting out minimum common criteria for waste management, applied to operations, growth projects and new businesses.

In October 2010, began the implementation of the Cerro El Minero Mine Closure Plan – Phase II (2010-2011), at El Teniente Division. This stage involves the withdrawal, transfer and disposal of approximately 20, 000 tonnes of stable arsenic waste. The total plan includes the removal of 100,000 tonnes from the safety storage facility at El Teniente Division within six years and at an estimated cost of US$ 36 million.

During Phase I (2009–2010), 22,000 tonnes of arsenic waste were removed and transported to an authorised external site for final disposal; no adverse incidents occurred.

Â

Liquid Waste

In 2010, an important achievement in liquid industrial waste (RILes) was that four discharges at Andina Division and six at El Teniente Division were formally eliminated with the Superintendency of Sanitary Services (SISS).

As a result, the general inventory of the Company’s liquid waste discharges went down from 25 in December 2009 to 15 in 2010. Liquid waste discharge is shown in the following table by Division:

(TABLA AQUI)

Codelco Norte and Gabriela Mistral deposit do not discharge liquid industrial waste into surface, continental nor sea water; therefore, Supreme Decree 90 is not applicable.

Codelco keeps its liquid waste information updated on its website www. codelco.com.

Â

Emissions, Energy Efficiency and Greenhouse Gases

During 2010, Codelco fully complied with all the emission standards applied to its smelters, both specific emission standards and those emissions regulated by decontamination plans.

Since the 1990s Codelco has been committed to reducing air emissions, through investments, management plans and emission control at its older smelters that were not originally designed to meet such standards.

The most relevant emissions are smelter gases regulated by emission standards, in the case of arsenic (As), or by decontamination plans, in the case of sulphur dioxide (SO2).

In advance of the promulgation of emission standards, in 2010 the Company began measuring the particulate matter baseline for PM 2.5 at all divisions.

The Energy Efficiency Plan, implemented in 2008, aims to reduce specific energy consumption in Codelco’s production processes. During 2010, division performance agreements were established on energy efficiency management, with monthly monitoring of key indicators of specific use in each process, covering more than 80% of total energy consumption (electricity and fuel).

Codelco has an energy data system to quantify greenhouse gas emissions, based on direct and indirect emissions, associated with energy consumption.

Codelco’s smelter emissions, compliance and energy consumption data by Division is available on its website: www.codelco.com.

Â

Biodiversity and Territorial Management

In 2010, major progress was achieved in territorial management. A corporate work team was formed; two workshops were held which resulted in the first Corporate Guidelines for Territorial Management and a division work plan was implemented in December. Biodiversity programmes were advanced, in keeping with Codelco Biodiversity Commitments, and initiatives and division projects were implemented.

Glaciers

The Corporate Glacier Strategy, approved in December 2009, defined a conceptual framework and applicable regulations; including guidance, definitions and objectives, and it determines the specific actions required to develop glacier studies, promotion, conservation, communication and engagement.

The strategy’s action plan was agreed in November 2010, by the Corporate Glacier Work Group. The plan set outs activities and deadlines for the actions included in the strategy.

Andina and El Teniente Divisions have conducted the corresponding inventory and diagnosis studies on their glacier status, based on the action plan.

Environmental Impact Evaluation System

During 2010, Codelco submitted 20 projects to the Environmental Impact Assessment System (EIAS): 18 were Environmental Impact Statements (EIS) and 2 Environmental Impact Studies (EISt). One environmental study corresponds to the New Mine Level project at El Teniente Division; and another to the Tailings Copper and Molybdenum Recovery Plant at Andina Division.

Among the initiatives submitted during the year, 11 were approved and 9 are currently undergoing approval.

Key projects approved in 2010 were:

- EIS – Chuquicamata Underground Mine, Codelco Norte Division.

- EIS – Ministro Hales Mine Modifications, Codelco Norte Division.

- EIS – Rajo Turquesa Remnant Mining, Salvador Division.

- EIS – Geological Prospecting, Andina Division.

- EIS – Rajo Sur Mining Project, El Teniente Division.

- EIS – Refinery Cleaning Sludge Transport, Ventanas Division.

- EIS – Anode Slime Transport, Head Office.

In Chile, 62 projects were approved in the mining sector during 2010, which required an estimated investment of US$ 7.139 billion. 63.5% of these projects were Codelco investments.

Â

Environmental Investment

During 2010, Codelco invested US$ 61.6 million in environmental and decontamination projects, such as:

Salvador Division

- Implementation of a wastewater and effluent management solution in Potrerillos.

Andina Division

- Construction of a water barrier to prevent leakages at OvejerÃa Dam.

El Teniente Division

- Implementation and construction of Car̩n Dam Р5th Stage.

Ventanas Division

- Construction of a new temporary hazardous waste facility.

Copper Life Cycle

Copper life cycle refers to the different stages of copper, from when it is mined to its final disposal at the end of its useful life. A life cycle inventory is a tool for measuring the estimated potential environmental impact associated with the production of a product unit during its entire life cycle.

During 2010, Codelco updated its life cycle inventory for its main copper commercial products. It also developed a carbon footprint calculator specific for copper product lines at each Division, which were given to employees to use in operations management.

Mine Closure

Since 2007, Codelco has ongoing mine closure management. The decisions made in this field have been as follows:

> Corporate Guidelines updated during 2010.

> Closure plans approved by SernageomÃn.

> Corporate closure cost estimate and updated provisions.

> Functional organisation, based on existing roles.

> Began closure project portfolio at divisions.

Closure activities were classified into areas that, in turn, were grouped into decommissioning and restoration categories, in conformity with IFRS.

In October 2010, the first Corporate Mine Closure Workshop was held, where opinions were shared with other mining companies, national regulations were reviewed, the division closure management was updated, in keeping with the relevant closure portfolio, and a concurrent closure plan was submitted for the period 2010- 2014.

The estimated cost of Codelco’s mine closures is calculated in current value, considering expense flows during the entire life of each mine. The first security payment is scheduled for 2014, if the draft Bill is enacted by Congress.

Social responsibility

As a fundamental part of social responsibility practices, Codelco conducts initiatives and projects to support the community within the framework of Codelco Buen Vecino (Good Neighbour). In 2010, these initiatives focused on: education, environment and entrepreneurship, directly associated with corporate definitions and regulations; the requirements of the division business plans, and the needs of the actual communities detected through direct engagement and ongoing communication with the communities, their leaders and with authorities in the influence areas of the mining operations.

Codelco Buen Vecino is a community management programme that groups all the initiatives against the adverse impacts caused by operations or new projects on local, social and environmental systems.

Codelco Buen Vecino projects also aim to help improve the quality of life of communities, establishing closer, transparent and ongoing collaborative relationships with social organisations, local authorities and the community in general. For this purpose, agreements were entered into with social organisations or public institutions.

Codelco’s community management has strengthened its reputation capital, giving it social licence to maintain and develop its production activities. According to Chileans, Codelco is among the most socially responsible companies in the country, perception that is reflected in the different internal and external surveys conducted during 2010 (such as the MORI survey; Are Chileans socially responsible?; the Prohumana survey and the Sustainable Codelco perception study, Gestra S.A.)

As for stakeholder management, a new version of the Community Engagement Manual was approved. A corporate decalogue was created for relationships with associates, contractors and subcontractors. A training scheme was also implemented for contractor companies on using e-billing, as part of a social responsibility agreement for supplier company development, together with the Chilean Inland Revenue (SII).

As for Codelco Buen Vecino initiatives and projects, the divisions, exploration and Head Office developed 401 projects in alliance with public and private institutions, totalling more than US$ 6 million (reference value: US$470).

Additionally, approximately US$ 2.6 million of remaining Sence funds were assigned to social grants for job training.

Codelco Buen Vecino

Chuquicamata Division and Radomiro Tomic Division

In 2010, grant funds were implemented jointly with Calama schools and social organisations which would be used to restore public spaces.

Other initiatives implemented were citizen safety and quality of life programmes, targeting vulnerable and low-income segments.

As for indigenous people initiatives, Codelco built a multipurpose room annexed to the Calama Museum to promote cultural heritage in the region, and activities were conducted in the context of the collaboration agreement with the Quechua community in San Pedro Estación, focused on the agricultural recovery and social development of this location.

Salvador

Complementary educational workshops were held for all primary schools in the province of Chañaral.

The division continued to support the pre-university colleges in Diego de Almagro and Chañaral, benefiting more than 500 teenagers.

Through the heritage recovery project at the Diego de Almagro and Chañaral museums, improvements were made to infrastructure and the classification of exhibition samples. Visits were also organised to archaeological sites in the province to promote respect and care for archaeological and historical heritage in the country.

Sustainable energy use was promoted, through homemade solar energy devices. More than 300 people were trained to use heavy duty machinery, electricity and homemade solar energy techniques. This initiative helps to create jobs in the province.

As in prior years, local organisations were directly engaged by developing handicraft and skills workshops; and work with the Colla Community is still in progress.

Andina

The Division continues to undertake direct work with social organisations; the local community’s requirements were channelled through regular working sessions in socially profitable actions and work.

Key projects were the consolidation of Los Andes Children’s Symphony Orchestra, two years after it was created and with the participation of 120 children and teenagers at risk.

Other initiatives were: contribution to primary education through Comics: 40 Years of Andina’s History; social reintegration of former drug users by fitting out Crehad Rehabilitation Centre; and social connectivity of district organisations by providing technological equipment and training for leaders.

Ventanas

It continued to invest in agricultural education and entrepreneurship in the Puchuncavà and Quintero municipalities. The division diversified its actions towards other community needs. Training workshops were held for social leaders, strengthening the neighbours-company relationship.

The Division continued to implement grant funds for community organisations, through an open and participatory methodology, which were awarded to 11 initiatives out of a total 80 submitted.

The Division also contributed to road infrastructure at La Greda (Puchuncavà district), where the main road pavement, curbs and shoulders were paved; it was a joint effort between the community, the municipality and Codelco.

El Teniente

Sustainability education promotion projects were implemented, such as “Yard Classrooms,” in the district of Alhué; and “My First Green School Bag,” at 19 nurseries in Rancagua.

Actions were undertaken to develop entrepreneurial and social-environmental skills among neighbours in ValparaÃso, O’Higgins and Metropolitan Regions, through solar energy and trade workshops.

The Company also contributed professional staff and machinery to help reconstruction efforts after the earthquake in six districts next to El Teniente operations.

Exploration

Exploration Management reported mining exploration activities using educational material to pupils at three Calama schools and two rural schools in the Salamanca district, so that the children could learn about the initial stage of a mining operation.

It also focused on promoting physical activity and health, personal development and environmental care, in the framework of projects carried out with primary schools in Calama. Part of the Salamanca community also received training on home safety.

Corporate Centre

Head Office promoted the creation of a Children’s Symphony Orchestra in the district of Mejillones. It consists of almost 80 children; many of these children are socially at risk and vulnerable. This project aims to replicate the successful experience of Los Andes Children’s Symphony Orchestra.

Codelco has been present in Mejillones for several years, for example, the Port Complex, E-CL (formerly Edelnor), the LNG terminal, employee camping sites of the former Codelco Norte Division and cathode shipments from Minera Gaby and Chuquicamata.